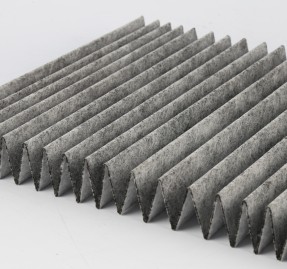

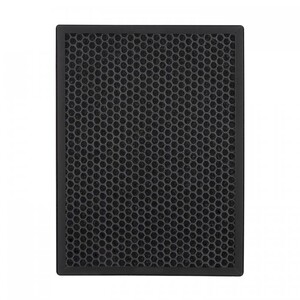

Compo make different types of activated carbon air filters such as honeycomb activated carbon filter, carbon pre filter roll, carbon pre filter sheet, activated carbon sponge, foam carbon filter, and carbon V bank filters.

The activated carbon air filters are effective in removing volatile organic compounds (VOCs), odors, and other gaseous pollutants from the air. Contact us to get quote.

The R&D efforts of our team resulted in several marketable features for our activated carbon air filters.

Can effectively remove 99% olatile organic compounds (VOCs), gas molecules, odors, smoke, and pollutants.

We offer low MOQ to support customers with trial order.

No matter carbon prefilter sheet, carbon filter roll or carbon pleated panel filters,We can offer customization service.

There are different kinds of raw materials for making activated carbon filters. Charcoal, coconut, wood, or coal are the common raw material for making activated carbon filters. In addition, during the production, it will be treated with additional chemicals to help entice the reaction between the carbon media and oxidation of polar or lower molecular weight compounds.Some chemical additive on carbon filterscan also help make the filter last longer.

The iodine value is a measure of the equilibrium mass of iodine adsorbed in excess on the surface of the activated carbon. It is a standard test method.

In adsorption theory, molecules of different sizes/functionalities will be physically adsorbed at surface locations of different energies accordingly. Chemists use different molecules to measure and simulate adsorption in a similar way. Since iodine is very small, it is a good indicator of the availability of activated carbon in very small/dense pores. The iodine value corresponds to the iodine equilibrium capacity of activated carbon, the amount of iodine adsorbed correlates with the increased porosity of the activated carbon and is used as a general performance indicator.

Iodine value is a widely used parameter for activated carbon testing due to its simplicity and quick testing of the quality of the adsorbent. It gives an estimate of its surface area and porosity. According to ASTM D4607, the iodine value is defined as the number of milligrams of iodine adsorbed by 1 gram of material when the residual concentration of iodine is 0.02 N (0.01 mol L-1), which is based on a three-point isotherm.

Treat the activated carbon sample with 10 mL of 5% (V / V) HCl. Boil the mixture for 30 seconds, then cool at room temperature. Immediately add 100mL of 0.1N iodine solution to the mixture and stir for 30 seconds. The solution was then filtered and 50 mL of the filtrate was titrated with 0.1N (0.05 mol L-1) sodium thiosulfate solution, using methyl ingot (or starch) as an indicator. The amount of iodine adsorbed per gram of adsorbent is plotted relative to the residual iodine concentration using the logarithmic axis. If the residual iodine concentration was not in the (0.008-0.04N) range, the procedure was repeated for each isothermal point using a different mass of carbon. Regression analysis was performed for three points and the iodine values were calculated as the amount of adsorbed at a residual iodine concentration of 0.02N.

What is the mechanism of the chemical activation of activated carbon?

Activated carbon uses potassium hydroxide or phosphoric acid to activate carbon materials, such as biomass, prior to carbonization and heat treatment. What is the nature of this chemical activation? What is the exact chemical reaction that takes place?

Sodium hydroxide hydrolyzes fats and they are converted into fatty acids and glycerol. It also hydrolyzes cellulose into lower molecular fragments. In addition, proteins are hydrolyzed by polyamide bonding. Zinc ions are part of the enzyme ethanol dehydrogenase. It can enhance the protein in the form of an enzyme. All these reactions contribute to the preparation before carbonization. After such treatment, useful low-molecular products can be isolated from the biomass.

After the adsorption of activated carbon saturated, there are several simple methods. For example, household formaldehyde removal activated carbon, pure water treatment activated carbon, etc., in the months of adsorption experienced. At this time, it only needs to be placed on the balcony to dry for a day to restore about 70% of the adsorption capacity. The drying can evaporate the water inside the activated carbon, and the high temperature can make part of the organic matter decompose to generate small molecules from the activated carbon pores.

When industrial waste treatment activated carbon is consumed and used up, i.e., when it is no longer carried out as required because it partially or completely fills the pores with impurities, it can usually be recirculated through a thermal reactivation process in a dedicated kiln. Waste carbon is usually divided into many general categories. Activated carbon from drinking water or household use is rarely contaminated with hazardous chemicals, but activated carbon from industrial or environmental processes (e.g. biogas) is highly polluting and is a hazardous waste. Therefore, activated carbon wastes from different use environments need to be handled separately to avoid cross-contamination. There are many environmental and economic benefits to recycling waste activated carbon rather than treating it to act as a substitute for virgin carbon. For example, the difference between waste activated carbon and reactivated activated carbon in many industries is not very big, and the first reactivation can reach about 80%-90% of the virgin carbon. However, in industry generally after the activated carbon is fully used it becomes a pile of hazardous waste and needs to be treated by a professional waste treatment company.

We satisfy all your air filtration requirements and would love to be your partner.

Be the first to know about regular product updates and promotion offers.

Copyright © 2022, Compo. All rights reserved. Powered by Compo

WhatsApp us